bowl centrifuge|labelled diagram of a centrifuge : distribute Wastewater sludge treatmentDuring the industrial process of wastewater treatment, huge quantity of sludge is produced. . See more Vamos apresentar os principais destaques e funcionalidadesda Pixbet. Após analisar as promoções e bônus da plataforma, notamos que este não é, de fato, o seu ponto forte. Portanto, nesta parte traremos uma avaliação sobre . Ver mais

{plog:ftitle_list}

• ג'ייסון סטיית'האם - ג'ונאס טיילור.• וו ג'ינג - ג'יומינג זאנג.• שויה סופיה קאי - מיינג ג'אנג. Ver mais

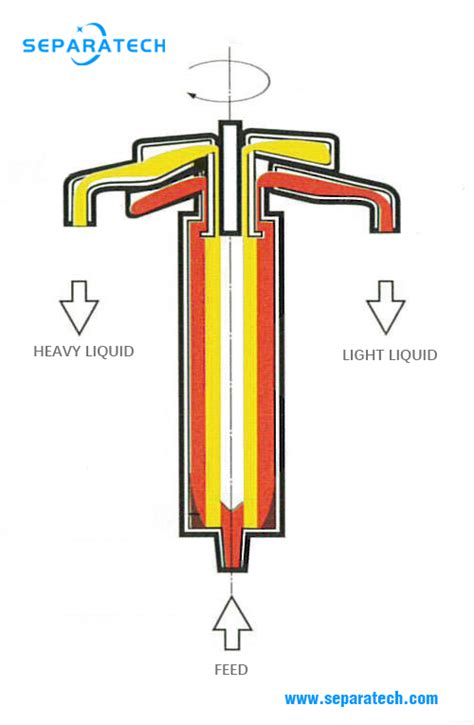

A solid bowl centrifuge is a type of centrifuge that uses the principle of sedimentation. A centrifuge is used to separate a mixture that consists of two substances with different densities by using the centrifugal force resulting from continuous rotation. It is normally used to separate solid-liquid, . See more

Wastewater sludge treatmentDuring the industrial process of wastewater treatment, huge quantity of sludge is produced. . See moreAdvantages• Rapid start-up and shut down.• Relatively simple installation.• Compact design.• Functions . See more

Process descriptionWith the help of helical screw conveyor, solid bowl centrifuges separate two substances with different densities by the centrifugal force formed under fast rotation. Feed slurry enters the conveyor and is delivered . See more

The post-treatment of the waste stream produced by the solid bowl centrifuge diverse depending on the industrial application. Since different industries have different feed for the centrifuge system, the waste stream will be different as well, and thus require . See moreSolid bowl centrifuge designs are divided into three different types based on the solid bowl shapes, which are conical, cylindrical, and cylindrical-conical. The choice of the centrifuge design in a particular industry is determined by the characteristics of . See more• The tested material is considered as an ideal material for the solid bowl centrifuge if the volume of solids and the volume of compaction come together within 90–120 seconds with a clear . See moreThere are various aspects that can be improved from the current solid bowl centrifuges in order to increase its performance and . See more

Learn about the different types of solid bowl centrifuges, how they work, and where they are used. Compare open-top, scraper bowl, and manual disc stack centrifuges and their advantages and disadvantages.A solid bowl centrifuge is a style of centrifuge used in the mining industry for separation of solids and liquids. A centrifuge is employed to separate a slurry that consists of two .

In many industries a solid bowl centrifuge is the tool-of-choice for separating solids from liquids, recovering solids or liquids from slurries, clarifying liquids, and classifying .

tubular bowl centrifuges

tubular bowl centrifuge diagram

us drop entry covid test

A lab scale tubular bowl centrifuge has the following characteristics: I r 1 = 16:5 mm and r 2 = 22:2 mm I bowl height of 115 mm I 800 revolutions per minute It is being used to separate . The open-top solid bowl centrifuge is the most basic industrial centrifuge design, one that people have used for at least a century. They tend to be small and simplistic, with a time-tested design. For that reason they are lower cost to purchase, but only capable of fairly rudimentary two-phase separations. A) The tubular Bowl centrifuge generally has a bowl with a diameter of between 15 and 50 cm which rotates at high-speed to generate a settling acceleration of up to about 18,000 g (where g is the acceleration due .

Alfa Laval trial decanter (solid bowl) centrifuges for mining Alfa Laval has a number of decanter (solid bowl) centrifuges available for trials on minerals processing slurries and tailings duties. The smallest of these are pilot units .The Hiller DecaOil centrifuge is a solid bowl decanter centrifuge especially designed for highly efficient, continuous sedimentation of solids and separation of one or two (non-mixable) liquid phases. The feed enters the rotating bowl through a stationary feed tube and is thrown radially outwards into the bowl through feed ports in the conveyor .Decanters and disc stack separators (also referred to as centrifuges) are both centrifugal separators. In many processes both decanters, discs stack separators and filters are used, in different stages of the process - or even used in series - to achieve the required separation result. . The centripetal force generated by the rotating bowl .

A decanter centrifuge, also known as a horizontal bowl centrifuge, solid bowl centrifuge or scroll centrifuge, is a machine used to separate a solid material from a liquid(s) using a high-speed and continual rotational process. While wastewater treatment of biosolids is a primary application, the separation of one solid material from oneSharples Super Centrifuges Overview of the Sharples Super Centrifuge. The Sharples Super Centrifuge is a machine for applying centrifugal force to a liquid. The rotor, called a bowl, has an opening in the bottom to allow the liquid to enter, and openings in the top of the bowl to allow the fluid or fluids to discharge.

A perforated basket (bowl) centrifuge is a filtration centrifuge. The separation is through a perforated wall based on the difference in the densities of solid and liquid phases. The bowl contains a perforated sidewall. During centrifugation, the liquid phase passes through the perforated wall, while the solid phase is retained in the bowl.

Tubular bowl centrifuges shine in clarifying small batches of heavily contaminated liquids, often playing a pivotal role in the early purification phases. Decanter centrifuges are the workhorses for managing hefty volumes of suspended solids or slurries, excelling in solid/liquid separation tasks.Horizontal Bowl centrifuges are also known as decanter centrifuges, centrifugal decanters or simply decanter machines and are primarily used for separation of liquids from appreciable amounts of solids. Decanters can separate over 50% (v/v) solids from liquids on a .Acting as two machines in one, the ANDRITZ screen bowl decanter centrifuges AS combine the clarifying benefits of the solid bowl centrifuge and add a final dewatering screen section to produce maximum dryness. It is best suited for crystalline or granular solids with free-draining characteristics and unit capacities of up to 100 t/h dry solids.

They can handle solid loads of up to 0.5% for solid bowl centrifuges and up to 10% for discharging centrifuges. Discharging disc stack centrifuge. Discharging disc stack centrifuges include a bowl with perforated holes that allow liquid to pass through the basket as it rotates. This prevents denser solids from passing through the holes.The SIEBTECHNIK TEMA decanter centrifuge is a continuously operating solid-bowl scroll centrifuge in tunnel or pedestal bearing design. Our decanters are individual, functional and versatile. They offer highly efficient separation of even the finest solid materials together with nearly complete clarification of the liquid phase.Solid-Wall Bowl Separator. There are two versions of disk-type separators with solid wall bowl: separators used for separating two mutually insoluble liquids, and clarifiers used for separating solids from liquids. All functions are similar to the function of the clarifier and separator types with self-cleaning bowl.Our decanter centrifuges separate fine solids from a suspension and optimally clarify the separated liquid. The Simp Drive ® concept and the adjustable impeller make it possible to adjust the residence time of the mixture in the decanter .

Actually two machines in one, it combines the clarifying benefits of the solid bowl centrifuge and adds a final dewatering screen section to produce maximum dryness. Decanter centrifuge A The solid bowl decanter is the basic, .

The ANDRITZ decanter centrifuges A are basic solid bowl decanter centrifuges to which features can be added for special applications. The solid bowl is ideal for clarification of liquids, thickening of sludges, and separation of solids.The centrifuge bowl’s design requires the heavy phase space within the bowl to be filled before the light phase enters the bowl. This prevents the light phase from exiting the bowl through the heavy phase pathway. A liquid seal is needed only in liquid/liquid separation cases wherein the lighter phase is the predominant liquid phase.

A Disc Stack Centrifuge primarily consists of the following key components: Bowl: The bowl is the central part of the centrifuge, where the separation process takes place. It contains a stack of discs that rotate at high speeds. Motor: The motor powers the centrifuge, providing the necessary rotational force to the discs.The Alfa Laval range of P2 decanter (solid bowl) centrifuges provides a cost-effective, high-performance solution for solid-liquid separation of erosive, corrosive and high temperature slurries. Highly flexible in design, they can be used in industries such as mineral processing, pulp and paper, coal tar, steel and chemicals as the wetted parts .

Bowl: The bowl is the main component of the solid bowl centrifuge and is typically made of stainless steel to withstand the high rotational speeds. It has a cylindrical shape with a conical end, which allows for efficient separation of solid and liquid phases. Scroll Conveyor: Inside the bowl, a scroll conveyor is installed. The scroll is a helical screw that runs .

Our precision cnc machined centrifuge bowls are machined from solid billets of aluminum for good chemical resistance and strength. Precision balanced for a long trouble-free life. Runs quiet and smooth. Bowl ships with detailed construction and assembly notes to build a complete centrifuge. New rotor design now shipping.These fine centrifuges have a horizontal or vertical, rotating, perforated (screen mesh) basket, within which resides a rotating scroll with screw design fins. . Comprising a horizontal, rotating cask or bowl, within which resides a rotating screw, the feed slurry enters the bowl, and its rotational g-forces push the solids to the outside .The decanter centrifuge cannot separate biological solids with very small density differences, such as cells and viruses. [5] A competitive process that is capable of separating these difficult-to-separate solids is the tubular-bowl centrifuge. The machine can .

A high-speed centrifuge is a type of centrifuge that can work at somewhat faster rates ranging between 15,000 and 30,000 revolutions per minute. High-speed centrifuges contain a device for regulating both the temperature and speed of the operation for the critical analysis of delicate biological molecules.The basic principle of the solid bowl centrifuge has been known since the end of the 19th century. Over the course of time, technological improvements along with the availability of high strength and corrosion-resistant construction materials have allowed solid bowlAlfa Laval's solid bowl decanting centrifuge for sludge thickening and dewatering in wastewater treatment.

us drop entry testing

solid bowl centrifuges

Resultado da Para ter acesso a todas essas facilidades, basta baixar o aplicativo na Apple Store (iOS) ou no Google Play (Android) e se surpreender com toda a .

bowl centrifuge|labelled diagram of a centrifuge